High-efficiency baghouse dust collectors designed for industrial particulate control in manufacturing, process, and material handling applications.

System Type – Pulse Jet / Reverse Air / Shaker Type.

Airflow Capacity – Custom engineered – from small to large industrial volumes.

Filter Media – Polyester, PTFE Membrane, Nomex, Antistatic.

Dust Types – Metal, Cement, Powder, Welding Fumes, Process Dust, Carbon, Rubber, Glass fiber, composite materials.

Compliance – Designed to meet CPCB / SPCB emission norms.

Industrial Baghouse Dust Collection Systems

Flowmax Filtration baghouse dust collectors are high-performance air pollution control systems designed to capture fine dust, fumes, and particulate matter from industrial processes. Our systems ensure cleaner air, regulatory compliance, and safer working environments.

Why Choose Flowmax Baghouse Dust Collectors

High filtration efficiency for fine particulate matter

Custom-engineered design based on process requirements

Long filter life and reduced maintenance costs

Compatible with abrasive, sticky, and high-temperature dust

Energy-efficient operation with optimized pressure drop

System Components

Filter bags.

Pulse jet or reverse air cleaning system

Dust hopper with rotary valve / screw conveyor

Induced draft fan and ducting interface

Performance Parameters

Filtration efficiency: up to 99.9%.

Operating temperature: customisable based on filter media.

Pressure drop: optimised for energy efficiency.

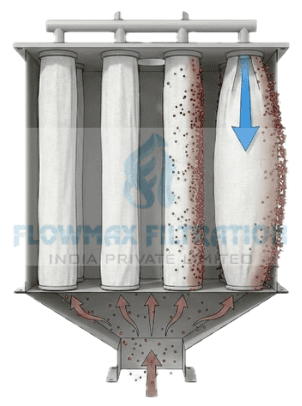

Dust-laden air enters the baghouse chamber

Dust particles are captured on the filter media surface

Clean air exits through the exhaust system

Accumulated dust is periodically removed using a cleaning mechanism

Dust is discharged via hopper for safe disposal

Applications & Industries

Rubber industry.

Cement plants and mineral processing.

Foundries and casting units.

Food, pharmaceutical, and powder handling industries.

Chemical and process manufacturing.

Activated carbon - destoner process.

Request a Custom Baghouse Dust Collection Solution

Our engineers design baghouse dust collectors based on airflow, dust type, temperature, and plant layout. Contact us today for a customized solution.